The Hardest Liquor to Make.

The Hardest Liquor to Get.

The Only One Worth Having.

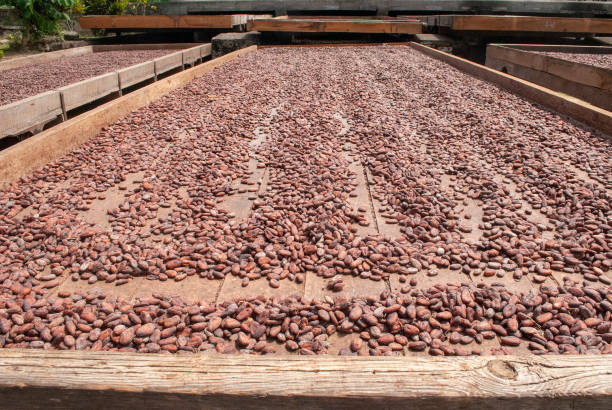

Vieroma is a handcrafted cacao-based liqueur built on one of the most demanding supply chains in spirits. Its cacao is sourced from remote regions of the Peruvian jungle, where reaching the farms requires hours of travel across rugged terrain, often involving river crossings and unpredictable conditions. The cacao is harvested by hand, fermented and sun-dried in the jungle, then transported through challenging Andean routes to the coast of Peru. Each batch is carefully inspected, hand-sorted, roasted, and crafted using natural processes with nothing artificial added. This level of difficulty, traceability, and care creates a rich, smooth, naturally complex flavor that elevates cocktails and stands apart on the shelf. It is one of the hardest liquors to make, one of the hardest liquors to get, but the only one worth having.